Versatile, US-Based CAD Outsourcing Services

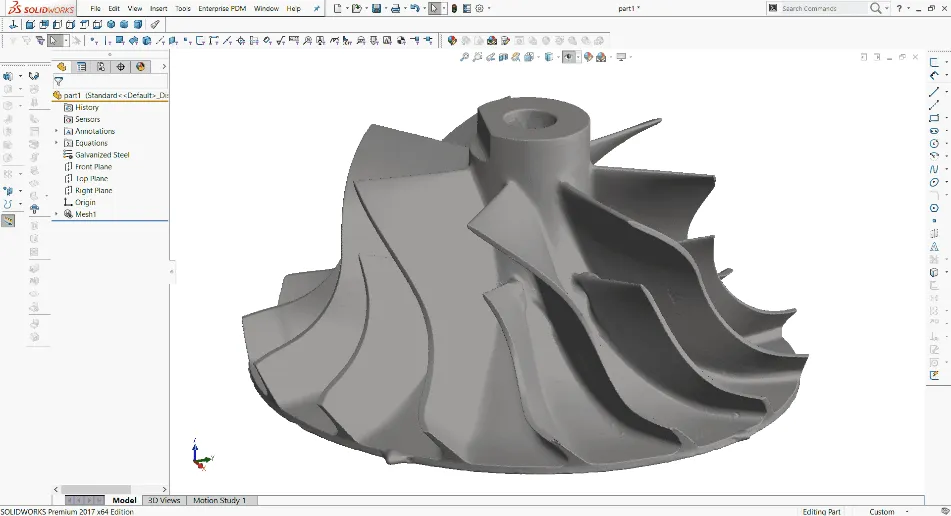

Our team of professional designers and drafters can handle your outsourced CAD designs. Our experts offer 3D CAD modeling, CAD conversions, CAD drafting services, and many other CAD services.

Our team of professional designers and drafters can handle your outsourced CAD designs. Our experts offer 3D CAD modeling, CAD conversions, CAD drafting services, and many other CAD services.

CAD/CAM Services is a US-based outsourced engineering company. Our team has an impressive history, completing projects in some of the most demanding industries such as aerospace, energy, and defense. With over 35 years of success, we have the skillset to tackle your project, and a portfolio to prove it. Our team is experienced in CATIA, Siemens NX, PTC CREO, SolidWorks, and Autodesk, and we can commit to tight timelines on the most complicated projects.

Isn’t it so hard to find the right people for your CAD engineering job? You have to find a team that communicates well, has great experience, has a good work ethic, and the ability to handle your most difficult projects. If you’ve been struggling to find the right outsourced CAD services, look no further.

Our team at CAD/CAM Services offers high-quality outsourced 2D and 3D CAD services that your team needs. We offer speed, precision, quality, and dependability that you won’t find elsewhere. Each of our clients have a dedicated CAD/CAM Services Project Manager that is here to communicate with you while leading our dedicated in-house team. We can provide an estimate in hours, and deliver projects in as little as 24 hours total. With our robust list of services, you’ll find the solution to your designing and engineering problems at CAD/CAM Services.

What can we do for you? 2D CAD conversions, 3D modeling services, CAD migration, 2D document scanning, 3D scanning, 3D printing, reverse engineering, drafting, simulation, sheet metal design, and much more. From professional as-builts to unique 3D CAD assemblies, our team of over 100 engineers and draftsmen is here to help.

Fill out a contact form so we can get in touch.

Describe your project, your goals, and any necessary details.

Attach your files using a secure DoD storage link that CAD/CAM provides for your data.

CAD/CAM provides an estimate regarding how long the project will take and how much it’ll cost.

We come to a verbal agreement and initiate a purchase order.

CAD/CAM begins to work on your project, communicating with you every step of the way, as frequently as you’d like.

You get your results. CAD/CAM delivers your final product in whichever format you need.

.svg)

.svg)

.svg)

.svg)

.svg)

.svg)

Sometimes due to the unavailability of spare parts, you have to make them yourself. This is the story of how we helped our client to recreate the missing parts with a full range of CAD design services: from CT scanning (due to complicated geometry) to...

Though 3D scans post-processing is more time and resource-consuming, it is impossible to recreate an original design from poor quality scans.

Despite being a relatively old industry, CAD software is still rapidly developing. This makes manufacturers change their focus CAD software. The migration process can be very time consuming, especially when you have your standards. We have proven that...

Sometimes photos alone can be a sufficient input for a CAD Perfect™ reverse engineering.

Even traditional sports with a long history can benefit from modern CAD technologies. New things can be created without breaking old rules. Parametric modeling helped us to create new putter head designs.

Greta Nintzel

Content & Digital Media Associate, Rich Media Team (amazon supply)

Angie

CTR USARMY CCDC ARL (USA)

Bill Johnson Jr.

Dallas Aerial Surveyors

Richard Schmitter

GTE Media Ventures

Pete Iannuzzi

Sony Music

Jerry McNabb

R Civ USAF – Tinkers Air Force Base

Bill Scott

City of Carrollton

Bo Daffin, CTA, RPA

Deputy Chief Appraiser of Central Appraisal District of Collin County

Greg Schulz

Richardson Independent School District

Phillip Schmidt, Jr.

District Plant Engineering Manager, UPS

Nathan Jones

City of Garland Texas, Engineering Department

Shane Duncan

Engineering Manager – W Machine Works Inc.

Nikko Meyers

Scan Direct

Ed Turk

V.P. Cornelius – Pierce Consulting Engineers

Chris Kidd

Dilon Technologies

Our CAD drafting services have a minimum order price of $195.

With a standard ‘D’ or ‘E’ size 2D AutoCAD *.dwg being $ 195.00. This is a fixed price for almost all 2D CAD work. *There is a small exception for GIS or very dense drawings.

All the CAD file formats are listed on this page but bear in mind that we also work with exotic and legacy CAD systems. After 31 years of providing CAD Services, we have run into almost any CAD file format.

Our facility runs three shifts and we're open and operating 24/7 to ensure the fastest turnarounds on the market. We offer turnarounds as low as 24 hours on our CAD drafting work. For larger projects, we can commit to aggressive timelines and tight turnarounds to ensure you meet your needs.

We like to bill our CAD drafting projects per hour. The rate depends on the CAD software that we use and any specialties or expertise that your project requires. It typically starts at $55 an hour, and you only get billed for hours that went directly to your project (no, you don’t get charged for any time spent daydreaming or working on other projects).

Often, we’ll include a limit to the cost, called a “not to exceed quote”. This will protect your budget and make sure you’re never paying too much.

We can also provide a fixed cost as part of our PO, if you would prefer that route.

To get the most accurate CAD drafting quote, we’ll need the following:

Fill out our quote form, attach your files, or simply send us an email. Tell everything about your project, like the model purpose.

For smaller files < 15 MB you can simply email them to us. For something larger, just drop them in any number of drop boxes like Dropbox, Google Drive, Microsoft OneDrive and others. Or if you would like, just contact us for a private, hardened link.

It is fine to use most any time of compression such as *.zip, *.rar, *.tar, *.7z, *.arc, *.LBR, and even *.iso images.

A direct email is [email protected]

We also use a hardened OwnCloud web file sharing platform for unlimited file transfers. We provide unique and very private Web Storage Portals, this also supports file syncing for extreme convenience for you. Because so much of our work is DOD or weapons design work, Security – and confidentiality is very important to us.

Yes. NDAs are a common part of our business. All data is yours – not ours, and treated as proprietary data and not for public consumption or use. Probably 70% of our work is under NDA agreements. We can generally get these signed within the day.

It depends on the scope of work:

Simple jobs have a lead time of 48 hours. Larger projects are delivered and invoiced weekly.

Yes, we did back in 2008. We started using Cad Perfect™ back in the early 1990s because all of our customers wanted only real Cad Perfect™ work. Back then the buzz words were terms like machine ready, or DXF Traceover and others.

The problem is, nobody wanted that. They all wanted drawings and models that they did not have to touch. Everybody wanted drawings just as if they hand redrew the work themselves.

Thus, Cad / Cam Services™ was the first company to start offering ONLY Cad Perfect™ work.

Yes we do, and have now for several years. In addition, we also support the industry specific plans as well.

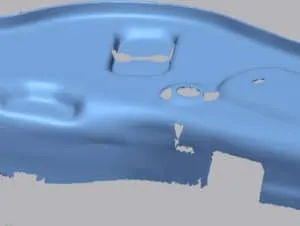

It depends on the complexity of the scanned model and material properties. As, for example, it may be much more complicated to properly scan an object with a reflective surface, than a non-reflective surface. It also depends on three main factors:

Simple quick cell phone photos are worth a thousand words to us. To know for sure you can request a quote. It is of course, free – and treated as if an NDA is already in place.

Some averages:

Because so much of our business is Aerospace related, our scanning – and the completed CAD file HAS to be within ±.005” anywhere on that part, we never use consumer-grade scanners. The scanners we use start at $25,000 and go up to $700,000 (CT) per scanner.

At any given time, we have in excess of $ 5 million just in scanning hardware we use. In addition, a hidden factor of scanning on any system is the assembly and clean up of any scan. The rule of thumb is a 2-1 ratio. So even with our experienced scanning staff, if we spend one-hour scanning; we will then spend an additional two hours of clean up and assembly before our CAD group gets the Point Cloud file to simulate or reverse engineer.

A point cloud is thousands if not millions of data points located in space by X, Y, Z coordinates. Images of this nature are often captured with Faro Focus or Artec scanners that specialize in large-area scanning. Most likely you obtain building and territory plans in this file format.

A polygon mesh is a set of triangles located in the same manner. These scans are obtained with Artec, Creaform, Enscan and other handheld scanners. Parts and reverse engineering device scans are usually polygon meshes.

The scanners we use are as accurate as the industry offers – from anybody at any cost. We use Faro and Artec 3D scanners, in addition to Faro CMM type arms, including the Surveyor tables. Depending on what scanner we use:

The typical AEC D & E size sheet is $135. There are possible discounts depending on the job size. The more you convert the less you pay. The bulk of the files we produce are for AutoCAD.

In order to make an accurate representation, you have to calibrate the original drawing, which may have deformed during its storage period. Non-dimensioned mediums need to be thoroughly calibrated before digitizing.

Parts of scanned data may be lost due to time and other factors. Because it is important to recreate the design intent, we need to recreate lost data.

You ONLY receive Cad Perfect™ files – as if you had drawn these by hand.

Using Revit, yes we do. Think of BIM as an intelligent 3D model of your building. We know exactly where all of the HVAC is, IT cabling, electrical, the cost of doors and windows, when mechanical systems need to be serviced, all the way to a room number with a phone number and IP in that room. In addition to our Ray Tracing technology to support some very life-like photo renderings.

The Department of Homeland Security protocol PPD-21 requirement has deemed that sixteen (16) industries and services are critical to our US Nations security.

These industries require additional security protocols when creating CAD files. CAD / CAM Services follows all of these requirements. Think of industries and info structures such as power, water, along with fourteen (14) other industries. For a full list please see Critical Infrastructure Products.

Mylar films can be stored in climate-controlled facilities. However, films get skewed and change sizes over time – ironically not linear. So what changes on one end, does not apply to what is in the middle, or the other end. We have seen ‘J’ size Aerospace Mylars (about 48×180”), vary by a full inch.

CAD/CAM Services utilizes a proprietary process to make Mylar raster images dead on a 5” or 10” grid. Our process was developed in conjunction with, and approved by Boeing engineers.

Per hour. Hourly rate depends on what CAD software used and typically starts at $75 per hour. In general, to make this process safer for you, we often provide you a fixed not to exceed the cost as well. That way, you are protected from an open-ended PO. However, the reality is our fees are based on time. In addition, services in say Catia or NX are more expensive than say Solidworks. Or, simulation services are commonly done by real engineers.

First of all, we need to know the target CAD system and whether you have an existing template, or set of CAD standards for this project.

The main question is the overall complexity. As each part and assembly consists of different features and elements the best way is to provide us with an example. Again, a picture is worth a thousand words.

If you already have a model and need us to improve it or update it in any way we need to know which dimensions and features are critical and which can be modified to achieve your desired result. Even a before and after example works very well. We started with x, and got to this CAD file.

We can also offer you better options if you provide us with the purpose of your project (demonstration, 3D printing, FEA Simulation, CNC manufacturing, etc.). This helps us better refine the task.

We create 2D drawings from our 3D models for QC purposes. We follow aerospace standards and deliver ±.005” accuracy models for all projects. All of our QC is done by a different person than the designer. On Catia work, we often use Q-Checker for Airbus.

We have a minimum order fee $150.

It all depends on the part’s complexity, size and structure.

We need to know whether you need your parts to be scanned by us. Or many times we can work with 3D scans provided by third-party companies. The quality of the scan is everything in our business. Anyway, we strongly advise you to use us for both the scanning and the CAD conversion aspects. That way, we can control the quality. Sometimes we receive poor quality scans which make it impossible to create truly Cad Perfect™ models for you. By all means, send us a couple of even cell phone photos, and the rough size of the object. Most of the time, this will provide us enough information to provide a real bid.

The price depends on the part complexity, size, as well as the target file parametres. We need to know whether you need full parametric models, and your desired accuracy. If you tell us the purpose of reverse-engineered models, we can often provide you with possible solutions. The target CAD software may change the price as well. This includes sophisticated Workstation add-on products such as Composites, Catia electrical wiring, mold design, and others.

We can provide ±.005” aerospace quality for every model. CT scanned parts can have even higher precision up to ±.001”.

We need to know source CAD and target CAD software. Since large quantity orders can be discounted by us you can provide us with the number of parts you need to be converted.

If you tell us the desired purpose of the conversion we can offer you some conversion options. We can also convert your files into vendor-neutral file types (.STEP, .STL, etc,).

Please email us even cell phone photos, and the rough size of what you wish scanned and converted [email protected].

You get native Cad Perfect™ files with the full-featured model tree (where applicable, since some file types have no trees), and features can be fully parametric. It all depends on your goals. We prefer to not translate any files. Our goal is to deliver to you a file that you do not have to touch. Our work is exactly as if you had reproduced that work in-house.

All the CAD file formats are listed on this page but bear in mind that we also work with exotic and legacy CAD systems. After 31 years of providing CAD Services, we have run into almost any CAD file format.

We support all the modern CAD systems including SolidWorks, Catia, Siemens NX, PTC Creo, Inventor, Revit, AutoCAD, and many others.

Yes, absolutely. We can perform legacy CAD conversions. Just send us some example files, and what CAD system we need to wind up in, and let us design the best solution for you.We have worked with old Computer Vision tapes, Anvil, and many other 1980’s systems.

A Finite Element Analysis (FEA) is a form of non-destructive testing (NDT) that shows how your part reacts to real-world loading events. A common example is running an FEA on a support bracket. The FEA will give results showing how much the bracket deflects, how much reactive force is seen, and the kind of internal stresses the bracket experiences.

FEA results will change dramatically based on the position and angle of the load, how much force is applied, the material properties of the part, and the design of the part itself.

An FEA is used to optimize a part before manufacturing begins. It allows you to find weak points within your part or assembly, and it will predict a failure before you physically make anything. This gives you an opportunity to fine-tune each part to optimize its size, strength, and cost before you start producing it.

The more information we have, the more accurate the simulation results will be. It also depends on what type of simulation you want to run. For a simple FEA, we can run an accurate simulation with just a 3D CAD model and loading/force/pressure information that you want to simulate.

Don’t have a 3D model? Not a problem, our team can make one for you from scratch, and then run an FEA on it.

For a more detailed answer, a well-run FEA will need:

• Material properties: What material is the part made out of? We can run different FEAs with different materials to help you pick the right one.

• Loading conditions: The size, location, and type of load you want to simulate.

• Bonding condition: How is the part held in place? Is it bolted, welded, or just sitting on a tabletop?

• A 3D model

• For other simulations: Please provide us with all thermal, dynamic, aero, and/or fluid flow information. Feel free to call us and we’ll walk you through what we need.

You bet we can. We created millions of files for Amazon’s online catalog, so no doubt we can help you. Click Link 1, Link 2 or Link 3 for some live Amazon examples. Simply select any file type from the list under the photo.

We directly support TraceParts.com, PartSolutions, GrabCAD, and several others.

There are no limits to creative tasks. Contact us and we will work something out. This includes part animation, expanded views, opening up assemblies, and full digital mock-ups.

We can stage what you want, or propose to you with our exclusive cinematic masterpiece.